Why Recycled Polyester is an Eco-Friendly Choice

In the face of climate change and environmental degradation, adopting sustainable practices is no longer optional. Recycled polyester (rPET) is gaining recognition as a sustainable solution that combines performance and eco-consciousness. From fashion to construction, rPET is transforming industries by reducing waste and conserving resources.

This blog delves into why recycled polyester is a preferred choice, its benefits, and its potential to shape a greener future.

What is Recycled Polyester?

Recycled polyester, also known as rPET, is a material derived from repurposed PET bottles and other plastic waste. It retains the durability, flexibility, and strength of virgin polyester, making it an excellent sustainable alternative.

Unlike virgin polyester, which is derived from petroleum—a non-renewable resource—rPET uses post-consumer plastics, significantly reducing dependency on fossil fuels. This transition from waste to value adds to its appeal in the era of sustainable innovation.

One of the primary reasons recycled polyester is gaining traction is its ability to mimic the properties of traditional polyester without compromising on quality. Whether it’s used in clothing, home furnishings, or industrial applications, rPET delivers durability and performance while keeping plastic out of landfills.

Environmental Benefits of Recycled Polyester

- Reduction in Plastic Waste: The world produces over 400 million tons of plastic annually, much of which ends up in landfills or oceans. Recycling PET bottles into polyester fibers provides an effective way to tackle this issue by diverting millions of bottles from landfills and waterways. According to Recycling International, innovative recycling technologies are ensuring better utilization of PET waste, helping industries contribute to a cleaner planet.

- Energy and Resource Efficiency: Producing recycled polyester requires up to 50% less energy compared to virgin polyester. The energy savings translate to a reduced carbon footprint, making it an environmentally conscious option for businesses and manufacturers. Additionally, the use of recycled materials often involves less water compared to traditional polyester production, further contributing to its sustainability.

- Reduction in Greenhouse Gas Emissions: Switching to recycled polyester helps cut down greenhouse gas emissions. For every ton of recycled polyester produced, industries save approximately 4 tons of CO₂ emissions compared to virgin polyester. This reduction is crucial in combating global warming and meeting international sustainability goals.

- Circular Economy Contribution: Recycled polyester aligns perfectly with the principles of a circular economy. By reusing materials that would otherwise be discarded, rPET contributes to a sustainable cycle of production and consumption, ensuring minimal waste. The circular economy approach not only reduces environmental harm but also inspires industries to rethink how materials can be reused and repurposed effectively.

Applications of Recycled Polyester

The versatility of recycled polyester makes it a material of choice for diverse industries:

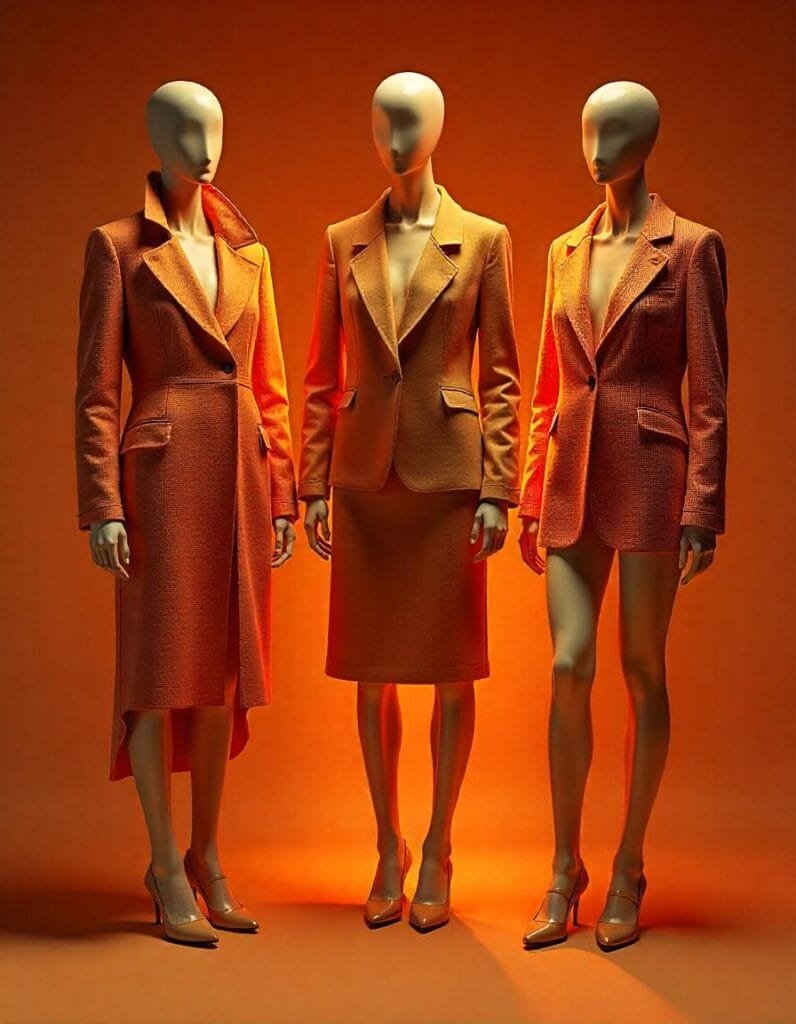

- Fashion and Textiles: Major global brands are now incorporating recycled polyester into clothing, footwear, and accessories, offering customers eco-friendly alternatives without compromising style.

- Home Furnishings: rPET is widely used in curtains, upholstery, and even bedding, combining sustainability with aesthetics.

- Automotive: rPET is widely used in car interiors, including seat covers and carpets, ensuring that vehicles are both durable and eco-friendly.

- Construction and Industrial Use: rPET finds applications in ropes, nets, and geotextiles, which are essential for infrastructure development.

From outdoor gear to reusable shopping bags, recycled polyester continues to replace virgin materials in both functional and creative applications, further solidifying its role in sustainability.

To explore more sustainable materials and practices, check out our RPG Industrial page, where we share insights on the latest eco-friendly innovations in the industry.

How Recycled Polyester is Made

The process of transforming discarded PET into high-quality polyester is fascinating. Here’s how it works:

- Collection and Sorting: Plastic bottles and waste are collected and sorted by type, ensuring only recyclable materials are processed.

- Cleaning and Shredding: The plastic waste is thoroughly cleaned to remove impurities, such as labels and adhesives, before being shredded into small flakes.

- Melting and Fiber Formation: The flakes are melted and re-spun into polyester fibers, which are then used to create fabrics or other products.

The beauty of this process lies in its ability to take waste that would otherwise pollute the environment and convert it into a usable resource. For more insights into how recycled polyester supports sustainable practices, check out National Geographic for their insights into tackling plastic waste.

Advantages for Businesses

- Cost-Effective Solution: While the initial setup for recycling may involve investment, rPET proves cost-effective in the long term due to energy savings and reduced raw material costs.

- Brand Reputation: Sustainability is a priority for modern consumers. Adopting recycled polyester not only reduces environmental impact but also enhances a brand’s reputation, attracting eco-conscious customers.

- Compliance with Regulations: Governments and international organizations are implementing stricter regulations around sustainability. Using recycled polyester can help businesses align with these standards while staying competitive.

- Innovation Opportunities: The demand for recycled polyester is driving innovation in recycling and manufacturing technologies. Companies that adopt rPET can position themselves as pioneers in sustainable practices, fostering customer loyalty and business growth.

Challenges in Using Recycled Polyester

While recycled polyester offers incredible benefits, there are challenges associated with its adoption:

- Contamination Risks

Improperly sorted or cleaned PET waste can lead to quality issues in the final product. Advanced recycling technologies are needed to overcome this challenge. - Awareness Gap

Many industries and consumers are still unaware of the benefits and potential of recycled polyester, slowing its widespread adoption. - Recycling Infrastructure

Not all countries have robust recycling systems to handle PET waste effectively, limiting access to recycled materials in some regions.

To overcome these challenges, governments, industries, and consumers must work together to promote recycling initiatives and invest in better infrastructure.

The Future of Recycled Polyester

The demand for sustainable materials like recycled polyester is set to rise. As awareness around climate change grows, industries are increasingly turning to eco-friendly alternatives.

Moreover, advancements in recycling technology are making rPET production even more efficient, paving the way for greater adoption across sectors. By choosing recycled polyester, businesses can not only reduce their environmental footprint but also actively contribute to creating a sustainable future.

Conclusion

Recycled polyester represents a step forward in tackling environmental challenges and promoting sustainable practices. By reducing waste, conserving energy, and cutting emissions, rPET is paving the way for industries to embrace sustainability.